Organizations are at different levels of robotic process automation RPA) adoption, from PoC and Pilot to multiple departments rollout. However, as the number of bots increases, business leaders face the unique challenge of managing an army of bots. These bots are required to work in a coordinated, process-centric manner and demand good governance. From allocating these bots to different processes, managing exceptions to auditing actions, organizations are geared up for human workers, but they do not have remedial actions for machine workers a.k.a. bots. Various departments, from process excellence, design and development, production and support to business operations, all of them need to contribute to a successful RPA strategy. While looking at robotic process automation software as a great process leverage and to witness a major impact on your organization’s strategic decision, you need to address these questions:

- Are your RPA bots resolving process bottlenecks?

- Is an RPA platform part of a larger process, or is it just a sweepstake for you?

- Is scalability a challenge?

- How are you planning to manage thousands of bots effectively?

- Will you be able to show and measure the actual impact of your RPA strategy in the long-term?

We at Newgen aim to address these questions and provide you with a Four-Step Approach that will help build and strengthen your RPA ecosystem.

Process Diagnosis

Process diagnosis leverages Newgen’s low-code process automation platform to identify areas in existing processes that are delivering unsatisfactory results and transform them into the most profitable ones with bots.

At this step, an organization’s existing processes are designed for the deployment of new RPA Bots. Here’s when the process excellence team understands how their ‘as-is’ process occurs in systems and where exactly bots can be deployed. Let’s dig deeper into how process diagnosis is done by leveraging Newgen’s low-code process automation platform:

- A real-world business scenario is created. The business scenario includes cost factors, SLAs, resource availability, KPI reports, and other dependencies.

- To identify the process bottlenecks, ‘as-is’ processes are simulated on Newgen’s low-code process automation platform.

- During simulation, new bots are (As shown in the figure 1) below, bottlenecks get auto-highlighted in red. With the deployment of new bots, bottlenecks are eventually dissolved, changing the red color into green.

- The simulator is re-run to monitor if new bots could remove the identified process

As a result of process diagnosis, the process excellence team knows about newly identified process model and efficient bots.

Process simulator depicts bottlenecks and KPIs

Design & Development of Bots

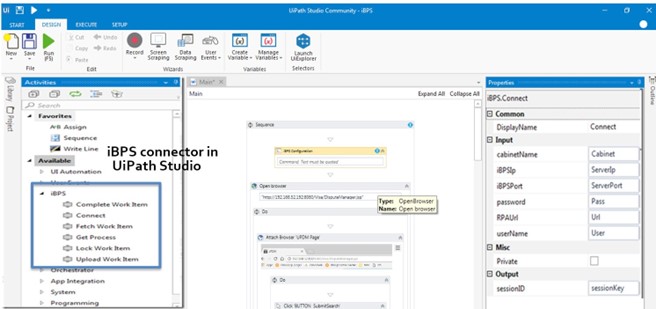

During the design and development of bots, the newly identified bots in Newgen’s low-code process automation platform are organized and allocated across process roadblocks by leveraging UiPath’s Studio. With the help of inbuilt connectors, each bot is loaded with a recorded script to mimic human actions.

Let’s deep dive into how the design & development of bots are performed:

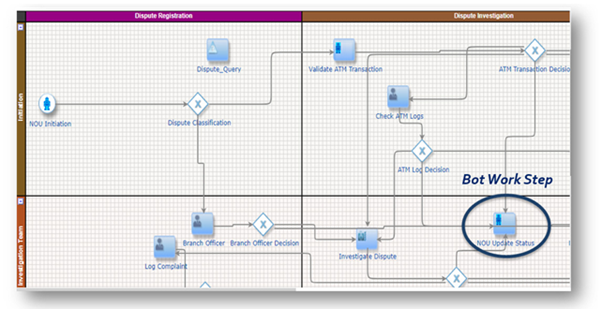

- Newgen’s low-code process automation platform process modeller is used for design

- Alerts and business exceptions are configured by the process

- The existing scripts, created during process diagnosis, are either moved into the production environment or new ones are recorded in UiPath

- These scripts are then made to interface with low-code process automation platform using low-code process automation platform connector in UiPath

- Real-time data and business exceptions are finally pushed to test the production environment and get insights into bots’ performance during the actual

With design and development of bots, a bot-enabled business process model is ready for its actual deployment

low-code process automation platform process designer depicting human activity being replaced by a bot

Extend Production Support

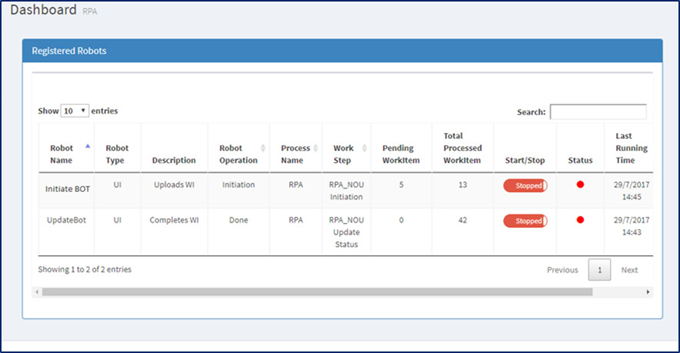

Once bots are designed and developed, this step is provisioned for monitoring the efficiency and overall productivity of deployed bots. Control Center helps stabilize the production environment and can be scaled as per business need. The capability to scale up production, clone bots, and distribute the workload between humans and bots are some of its key offerings.

low-code process automation platform connector on UiPath studio for seamless integration

Here’s a quick mention of steps that are performed during this step:

- With a bot-enabled business process model, the addition and configuration of new bots are done to meet business

- Bots are integrated with script(s) that were created during the design & development

- Bots are turned on/ off as per business

- Production is scaled up/down by adding and removing bots across the

- Bots’ running efficiency is checked to monitor the overall health of a process.

With bots in place, the production environment is controlled via a control center. In case the actual production graph is not smooth, the system automatically makes a note of all spikes (errors and exceptions) in a separate document for root-cause analysis.

Robotic Control Center depicting the list of bots with other details

Measure Business Impact

During this step, business operation managers assess if the newly identified bots could deliver the promised business value. They understand process variations and deviations in a hassle-free manner. Further, they know where exactly their workforce efforts can be channelized instead of being involved in dull, boring, and repetitive tasks.

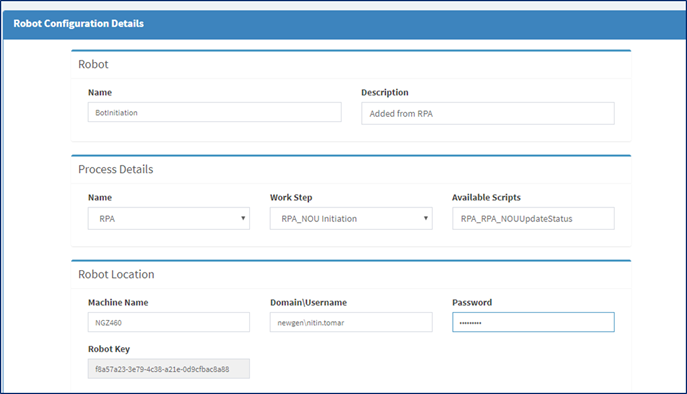

Defining a Robot configuration

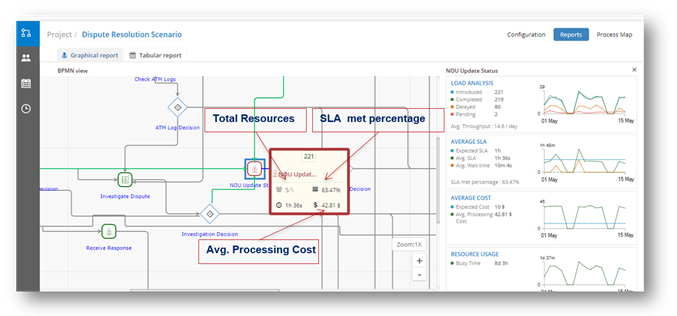

One of the ways to assess the overall business impact is by using Business Activity Monitor (BAM). Using BAM, operation managers generate different types of business reports, such as SLA breaches, cost-effectiveness, bots’ efficiency checks, and others. These reports estimate data points, such as the time allotted v/s the actual time taken by bots in the production environment.

Here’s a quick rundown of steps performed during this step:

- Operation managers use BAM to generate different types of reports.

- Data points are for instance, time allotted v/s actual time taken by bots in the completion of task(s).

- Rules & filters are applied on the intuitive dashboard to fetch the required business data that is further sliced and diced as per business requirements. Bars & graphs are generated to draw historical comparisons.

- Finally, published reports are used to track if operational efficiency goals have been met by the implementation of bots. Feedback can also be given for further improvements.

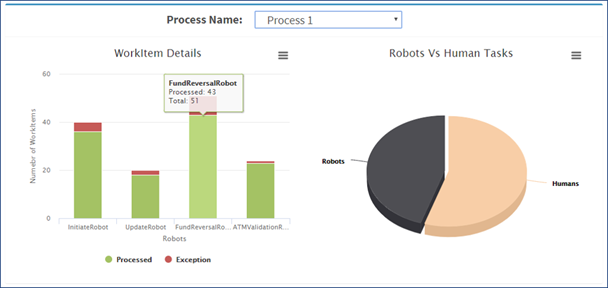

Graphs depicting exceptions faced by bots across operations and workload distribution between human and bot

With bots in place, operations managers derive useful insights to assess if they have accomplished broader digital transformation goals.

In conclusion

With Newgen’s four-step approach, you can amplify the overall impact of your organization’s RPA strategy success. You can manage an army of bots and build an effective ecosystem of bots in the long run. Also, you can meet your current business needs, cater to future requirements, and yield a higher ROI.

You might be interested in